Bentonite is Naturally occurring hydrated aluminum silicate (Al2O3, 4SiO2 H2O).

Types of grades we produce

| Properties | Protocol | Unit | Result |

| Free Swelling Volume 2 gm/100ml | ASTM D 5890:1995 | ml | 32-34 |

| Methylene Blue Absorption Value | API spe 131:2004/ ISO 10416:2002 | mg/gm of clay | 400 – 450 |

| Liquid Limit | IS:12446-1988 | ml/100 gm | 600 – 700 |

| Gel Time 2.5gm/25 ml | IS:12446-1988 | second | Instant. |

| Gelling Index | IS:12446-1988 | ml | 85-90 |

| Moisture Content % by weight | API Spec. 13A:2004/ ISO 13500: 1998 | % | 10.0 – 12.0 |

| PH Value 2% slurry | IS:6186-1986 | pH | 9.5 – 9.9 |

| Green Compression Strength Bentonite : Water :10:4 55-60 A.F.S Sand | IS:12446-1988 | psi | 12.5 |

| Wet Tensile Strength | IS:12446-1988 | N/cm2 | 0.16-0.20 |

| Dry Mesh % Passing 200 B.S.S | IS:6186-1986 | % | 85 Minimum |

| Properties | Protocol | Unit | REQUIRED | RESULT |

| Viscometer Dial Reading at 600 rpm | API Spec. 13A:2004/ ISO 13500: 1998 | r/min | 30 | 35-40 |

| Yield Point / Plastic Viscosity Ratio | API Spec. 13A:2004/ ISO 13500: 1998 | – | 3 Max | 2.5 |

| Filterate Volume | API Spec. 13A:2004/ ISO 13500: 1998 | ML | 15 Max | 14 |

| Moisture Content | API Spec. 13A:2004/ ISO 13500: 1998 | % by weight | 10.0 max. | 10 |

| Dry Screen Analysis(Residue Greater than 75 Microns)% | API Spec. 13A:2004/ ISO 13500: 1998 | % by weight | 4.0 max. | 3.0 – 4.0 |

| Properties | Protocol | Unit | Required | Result |

| Yield | OCMA DFCP-4 | bbls/2000lbs | 90 min | 99 – 115 |

| A.P.I. Filterate Loss | OCMA DFCP-4 | ml | 15.0 max. | 13 – 14 |

| Moisture Content | API Spec. 13A:2004/ ISO 13500: 1998 | % by weight | 15.0 max. | 10.0 – 12.0 |

| Dry Screen Analysis 100 Mesh Sieve | OCMA DFCP-4 | % by weight | 98.0 min. | 98.5 |

| Wet Screen Analysis 200 Mesh Sieve residue | OCMA DFCP-4 | % by weight | 2.5 max | 1.75 |

| Properties | Protocol | Unit | Result |

| Liquid Limit | IS:12446-1988 | ml/100 gm | 650-700 |

| Moisture Content | API Spec. 13A:2004/ ISO 13500: 1998 | % by wt. | 12.0 Max |

| Dry Screen Analysis (residue on 75 um sieve | IS:6186-1986 | % by. Wt. | 25.0 max. |

| Free Swelling Volume 2gm/100ml | ASTM D 5890:1995 | ml | 30 CC |

| PH Value of 5% gel | IS:6186-1986 | pH | 9.5 – 10.0 |

| Loose Bulk Density | IS:7589-1974 | gm/ml | 0.85 -1.0 |

| Gel Time 2.5gm/25 ml | IS:12446-1988 | second | Instant |

| Swelling Index | IS:12446-1988 | 10ml/gm | 28 |

| Gelling Index | IS:6186-1986 | ml | 75 |

| Methylene Blue Value | API spe 131:2004/ ISO 10416:2002 | mg/gm of clay | 350 – 400 |

Mixing 5 minutes on REMI MIXER (at 4000 rpm) in distilled water at 20 degree centigrade

| High Yield 120 | High Yield 145 | High Yield 180 | |||

| Concentration in pure mud | G/l | 60 | 40 | 30 | |

| After 1 hour | |||||

| Marsh Viscosity (API) | API RP 13B-2,3RD ED:1998 | Sec. | 40 min | 40 min | 40 |

| Rigidity (API) | Lbs/100ft2 | 3 min | 3 min | 3 min | |

| Filterate (API) | IS:6186-1986 | ml | 20 max | 20 max | 23 |

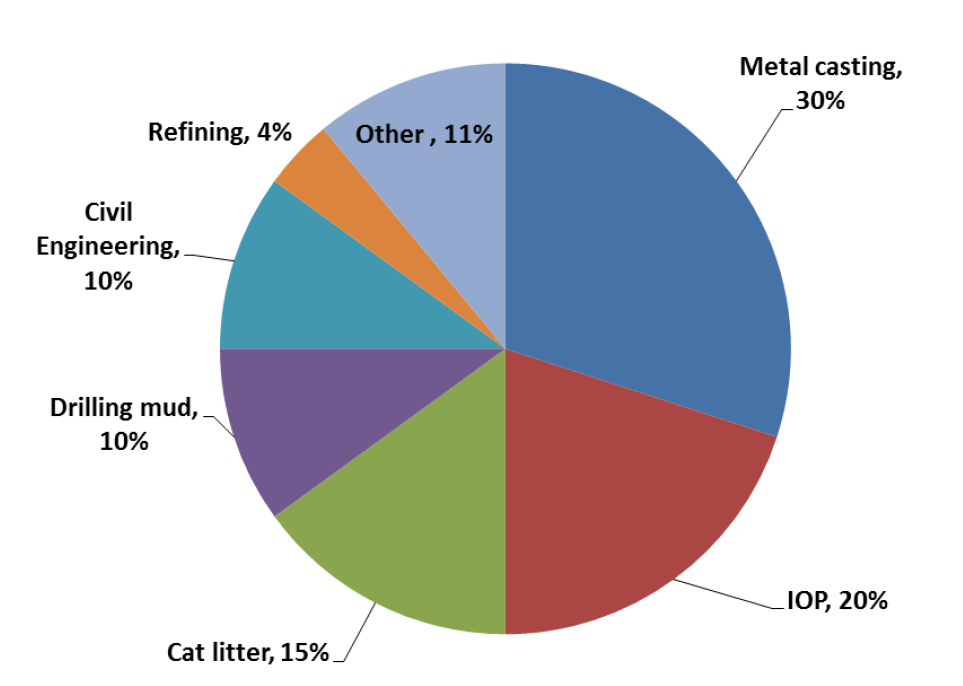

Well drillers use Bentonite when drilling oil or gas wells. Bentonite will absorb 10 times it weight in water. The bentonite clay is mixed with water and other minerals to form a drilling mud, which seals up the wall of the well bore and allows the rock chips to be pumped back to the surface.

Iron ore manufacturers add Bentonite to crushed taconite to form pellets, which can then be transported to a steel mills.

Because Bentonite will absorb moisture, new applications are continually being developed. Clumping cat litter and toxic waste cleanup are two of those new markets.

Foundries, Well drillers, Iron ore manufacturers and producers of kitty litter are the main consumers of Bentonite.

Bentonite is also used as a:

- Clarifying agent for wine, vinegar, fruit juice, beer, oils

- Sealant in sanitary landfills and lagoons

- Water purification systems

- Binder in fertilizers and animal feed products

- Carrier for insecticides.

Sodium bentonite Clay

Sodium bentonite has proven to be one of the most effective sealants on the market. The fact that sodium bentonite swells many times its mass, then forms a strong water and chemical proof seal makes it an ideal, inexpensive, permanent, and easy to install liner. Because it contains no chemicals, no additives, nothing toxic, sodium bentonite is environmentally-friendly.

Applications of Sodium Bentonite

- Pond Sealing– Pond sealing is one of the applications where sodium bentonite is most popularly used. Water often seeps into the soil that forms the sides or the bottom of a pond. By applying sodium bentonite onto the soil that surrounds a pond, the issue of water seepage is effectively prevented. Sodium bentonite creates an impermeable barrier between the soil and the water, allowing the pond to retain its volume of water.

- Lagoon Sealing– The way that sodium bentonite works on lagoons is extremely similar to that of pond sealing. What may differ is the process and technique of application. The method of application differs based on the size of the water body, its depth, and the pressure at waterbed.

- Well Casing and Sealing– Wells are extremely convenient and effective ways to store water. Creating a well though, is not as straightforward as one might imagine. Wells need to be created using materials that do not allow for water seepage to avoid contaminating the water supply and to keep water in the desired area. Applying sodium bentonite to these materials will ensure that the well remains leak free.

- Well Abandonment– When old wells become dried up or are no longer used, the well hole must be sealed up. Using sodium bentonite during the well abandonment process will prevent ground water contamination, which could cause serious harm to people or animals.

- Landfill Liner– Sodium bentonite is also often used as a landfill liner that prevents the toxic chemicals present in landfill sites from seeping into the soil and surrounding ground water or streams.

- Slurry Walls– Slurry walls are built to allow concrete structures to be built around nearby water bodies. These walls are meant to prevent water seepage and the creation of soft soil. Slurry walls are made using sodium bentonite to ensure there is low permeability between the groundwater and the structure to be built.

Calcium Bentonite Clay

It also has high adsorption and absorption capabilities.

Industrial Applications of Calcium Bentonite

The major industrial applications of this popular Bentonite clay are signification in various industries:

- Cosmetic industry – This clay is used in all kinds of cosmetic products like foundation, skin lighteners, facials, pancakes, compact powders, anti-acne agents, and lipstick binders.

- Iron and Steel Foundries – It is mainly used for smaller castings using wet or green molds.

- Drilling Mud – The clay is also used as drilling mud with different composition adjusted as per the requirement of the depth and other factors.

- Pelletizing – Since many years, this mineral is used as a binder in producing pellets of material. These are the natural or activated sodium Bentonites which are best to form good pellets with dry strength.

- Absorbents – The calcium bentonite clay is used in the clarification of oils, wines, as well in the bleaching. They are also important in purifying the contaminated water.